Sustainability is a choice.

Change Starts at Source.

Here at Source, we embrace sustainability from both angles:

1. Sourcing and promoting sustainable products

2. Choosing environmentally friendly ways to operate our business

From elevating our most sustainable suppliers to implementing energy efficient operations and power sources (EVs, solar, paperless), we are committed to the here and now as well as for future generations.

- Making sustainability accessible

- Responsible supply chains

- Delivering innovative solutions

- Source is fully independent and not tied to a buying group

Our Business

- Investing in a diverse workforce

- Taking action on climate change

- Supporting charities and local communities

- Providing a safe, enjoyable and flexible working environment

Our Customers

- Providing sustainable solutions

- Expert advice on emerging trends and products

- Nimble and reactive customer service

- Best in Class online customer account system! (thanks, Madison)

That's why sustainability is core to how Source Supplies does business and how we'll grow in the future. It's not because being green is fashionable - it's because it makes the utmost business sense. From sourcing products in an ethical and responsible way, to consolidating them in an environmentally efficient operating model, our approach helps us to minimise risk while maximising value.

Our goal is for Source Supplies to be seen as a socially and environmentally responsible organisation that inspires and implements solutions that protect the environment, while being commercially successful for our employees and shareholders.

WHEN IT COMES TO SUSTAINABILITY,

WE'RE COMMITTED TO LEADING THE WAY.

Source is a trusted partner for organisations at national and local level from a variety of sectors involved in cleaning and hygiene.

Simply put, we're constantly aiming to be the most valuable and trusted link in the chain.

Why is our team on the homepage and not buried in the footer under 'About Us'?

Because without our hard working, loyal team, we're nothing. The culture at Source is far from formal but this doesn't detract from the professionalism when it comes to providing our customers with what they need.

The team work their socks off to ensure our reputation for being helpful, responsive, knowledgeable and friendly is not just upheld, but enhanced whenever possible.

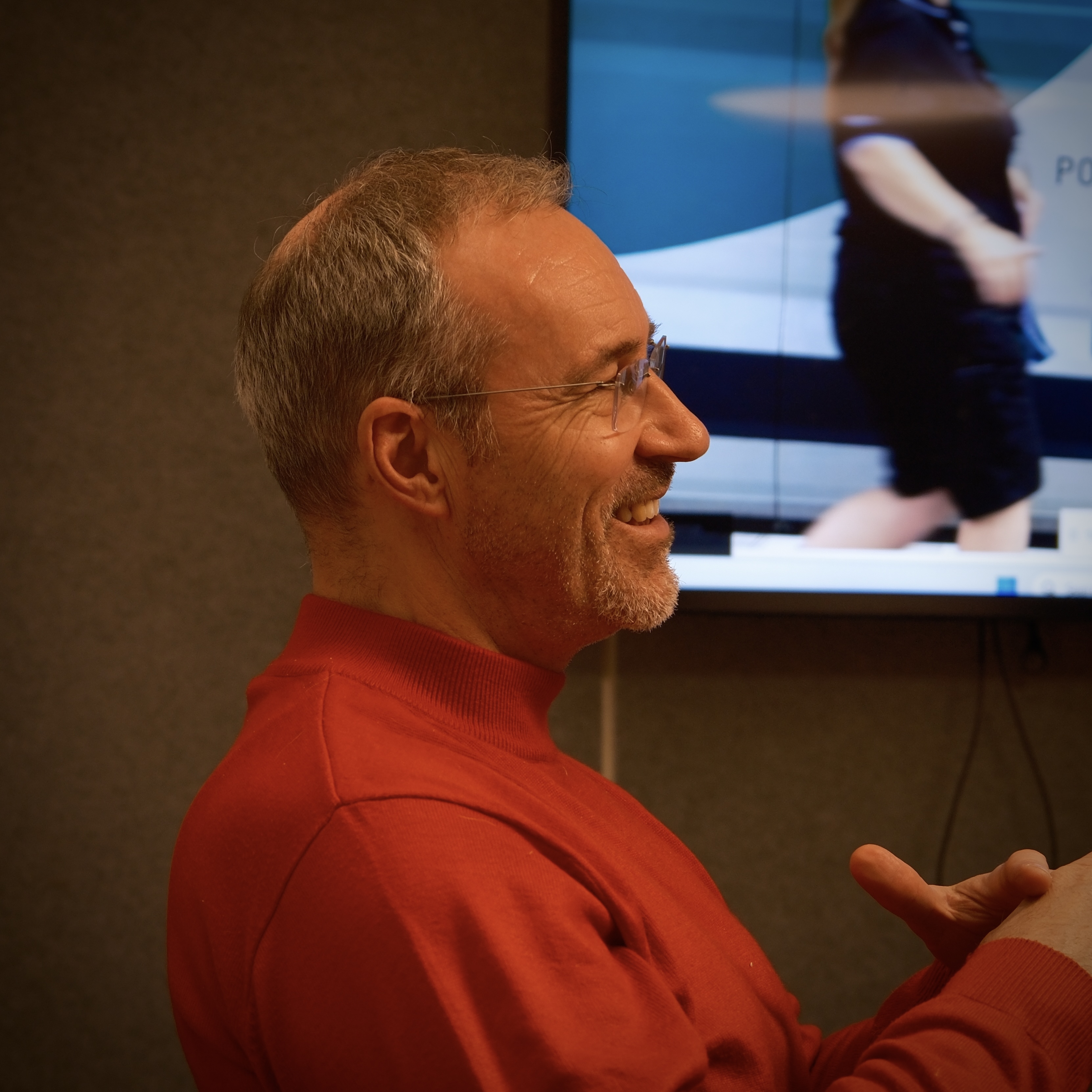

Dave Piper

Director

The DNA of Source comes from Dave. An absolute can-do attitude towards customer service underpins the business and creates the benchmark for the team.

Dave oversees many facets of the business, from Operations to Finance and together with Ollie, steers the ship strategically through constantly changing times.

Source was a light bulb moment Dave had back in 2005, pairing up with Ollie in 2010, to create a business that has a culture that values staff happiness and customer satisfaction equally.

Dave is still the go-to for many customers and staff alike as there is no one else that lives and breathes Source like Dave!

Former professional and semi professional footballer for 15 years, Dave, like many of his Source colleagues, can often be found on the golf course, somehow still playing to a double figure handicap.

Ollie Rastall

Director

With big ideas of business growth from the outset, Ollie set about developing the customer base from humble beginnings, cold calling from his bedroom whilst Source was operating from a shipping container.

Bringing the fledgling company to the attention of the industry with a disruptive brand and left field marketing was the modus operandi in the early days. Attracting intrigued prospective customers and convincing them to try the overly high bar of service Dave and Ollie set, facilitated year-on-year growth since 2010.

With the business now well established, Ollie is motivated by bringing innovative and sustainable products and solutions to the attention of, well, anyone who'll listen or watch his videos!

Ollie and Dave work closely together on the positioning of Source in the market and ensure the business is optimal in these constantly choppy commercial waters.

When Ollie isn't cycling or being carried round the golf course by Dave, he's out there banging the Source drum.

Our Team

Stuart

Operations Manager

There isn't an order that can pass through Source without Stu knowing about it. The most dedicated Ops Manager out there! When he's not at Source, he's playing golf.

Nyree

Accounts & Office Manager

Our longest suffering employee, Ny runs Source office and is the glue amongst us all.

Accounts and Office Management are Ny's daily roles when she's not looking after us all.

Tim

Internal Account Manager

Coming from a longstanding career in customer service, Tim is utilised by several divisions at Source with his key area being customer service. He looks after installations too, being very handy on the tools!

You can hear Tim a mile away with his infectious laugh and constant chatter about golf!

Sarah

Key Account Manager

Sarah looks after the orders for key accounts, overseeing the full delivery cycle and ensuring an excellent customer experience. With four sons, Source is her downtime! Except the fact her husband, Stu, sits 10 yards away!

Byron

Washroom Services Manager

Byron is as laid back as they come but also has unique work ethic that sees him go far and wide for Source.

The softly spoken Northern Irishman is a long serving member of the team and enjoys 18 holes when he's not looking after Washroom Services.

Mags

Source Washroom

Mags is incredibly hard working and never seems to stop! An integral part of our washroom services team who leads by example and is respected and liked in equal measures by customers and colleagues.

When Mags isn't working, she is renovating her house!

David

Warehouse Manager

Affectionately known as 'Big D', you'll never see this man in a bad mood. He works his socks off for Source and takes pride in his excellent relationships with customers.

David is a reliable member of Source, and was promoted to Warehouse Manager in February 2024.

Tony

Driver

Never before have London deliveries been completed with less fuss. Tony is in the Big Smoke every day and gets his work done accurately and efficiently despite the stresses of Central London traffic. Always chirpy, Tony is great to have around

Rob

Source Toiletries

Rob looks after our Toiletries Division, supplying feminine hygiene and toiletries to a variety of sectors. Rob's customers include 5 star hotels, commercial cleaning companies,

Lou

Driver

Lou is an early riser and is in and out of London before most of us are even thinking about lunch. Wife to Tony, Lou has a relaxed and friendly nature which has already endeared herself to her team mates and customers.

Debbie

Driver

Oxford Colleges are in the safe hands of Debs. This can be a tricky remit with the network of delivery points within the historic colleges campuses but she takes it in her stride. Debs has a the bubbliest of personalities and is really popular with, well, everyone!

Tomasz

Source Washroom

Tomasz takes his work seriously and completes it with pride. One of the more private members of Team Source, Tomasz is a key player in the Source Hygiene Washroom Services machine.

Tomasz sometimes can be found helping out Stu with Source deliveries, along aside his main role reporting into Byron.

Przemyslaw

Source Washroom

Affectionately known as 'Niko', we've never seen him without a smile on his face.

As with all of Byron's Source Hygiene team, a strong work ethic is ever-present with Niko and he is a dream to manage. He does a great job with zero fuss and is a credit to Source.

Adam

Driver

Adam worked as Menswear Manager in M&S for over 20 years, gaining lots of experience in customer service and retail. A career change to Source has done Adam the world of good and he enjoys meeting our customers on a daily basis. Adam is deaf from birth so uses his lip reading skills and sign language to communicate.

Paulina

Source Washroom

Having worked in washroom services for PHS for several years, Paulina came to join her friends at Source Hygiene and has been a brilliant addition to the team.

Andrew

Driver

Andrew comes to us with loads of valuable experience in various industries that include 14 years in the British Army in the Royal Electrical and Mechanical Engineers, 24 years in IT and another 14 years working on doors in pubs and clubs!

Jono

Courier Supervisor & Driver

Jono is the Source boomerang. In his 4th stint with Source, he keeps coming back to his spiritual home and we're thankful to have him.

Jono has a can-do attitude and applies himself to a varied range of tasks, using the knowledge he's gained over many years with the business. Jono is a keen footballer and roller hockey player but age is creeping up on the big man and he's contemplating hanging up the keeper gloves... don't do it, Jono|!

George

Warehouse

Bea

Administrator

Bea came to us as our Courier Coordinator, managing shipments for a large, national retail customer.

Natural progression was to move into a role that had more scope for progression. Bea now looks after the administration from several areas of the business.

Aaron

Assistant Operations

Aaron came to us from a long stint at Morrisons where he worked straight from school, gaining multiple promotions.

Fitting right in with the Source culture, Aaron is a very committed hard working young man who also knows how to party. Jigsaw complete!

Darren

Driver

Darren is a softly spoken chap who is one of our super reliable drivers.

Away from Source, Darren is a top darts player and also is the Manager of his son's U14 Football Team.

Charley

Driver

Charley is a semi-professional footballer playing for Woodley FC, playing at centre half.

Charley loves going to heavy metal gigs and adrenaline based holidays. Dark horse!

Matt

Warehouse - Courier Supervisor

Matt is hails from Poland and is a super interesting chap. He loves to travel (South Korea, USA, Japan in recent times) plays the Saxophone and keeps guinea pigs!

A larger than life character, Matt has always got a smile on his face.

Ruby

Source Mascot

They say dogs have a calming quality... so true with lovely Ruby. Part of the team, everyday.